One of the challenges of the fusion machines … [read more]

Category: Newsline 2020

Weekly LIPAc highlights (14/December-18/December)

Facility Inspection

On Wednesday 16th December the facility inspection was completed successfully. The Injector operation was very stable at 50% duty cycle (dc) and 100mA of total extracted current from deuterium plasma. A positive notification of the acceptance of the inspection is expected shortly. To be noted that this facility inspection could be the last one until completion of the planned LIPAc operation.

HEBT (High Energy Beam Transport) commissioning

This week more remote sessions with CIEMAT support took place for the commissioning of the different Beam Instrumentation equipment installed in the HEBT line (SEM grid, Slits, Faraday Cup).

Beam Dump

The installation of the planned upgrade in the deaeration loop (oxygen control loop) of the Beam Dump continued all the week.

Vacuum systems and ancillaries

RFQ and HEBT cryopump groups have been safely stopped (the RFQ cavity is still pumped by one turbomolecular pump, the HEBT is kept in static vacuum). The same will be done for their cooling skids. The systems are maintained in a safe situation because of several maintenance activities planned during the winter break on compressed air system and on common skids.

Global Alignment survey

The preparation of the global alignment survey of the LIPAc continued and the work in the vault will start this week.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.

Weekly LIPAc highlights (7/December-11/December)

Injector conditioning

The Injector operation continued this week at 50% duty cycle (d.c.) and 100mA of total extracted current from deuterium plasma. The beam was very stable and the ramp-up time to the target dc could be improved. The target performance for the facility inspection (50%dc @100mA) was confirmed. On Friday afternoon a self-imposed inspection was performed with measurements of radiation level while the injector operates at 50%dc @100mA. The facility inspection is scheduled next week, on 16th December.

Radio Frequency (RF) System

After the start-up of the entire RF system last week, a few additional actions to improve the stability of the system were identified. Next week the final tetrode of chain 2A will be extracted for high voltage conditioning. In parallel the key upgrade of the PYS-LLRF interface to improve the time response of the fast interlock is ongoing. The performance checks and further improvement were completed on the RF module 4 and the RF team target to propagate the modification to all the modules by mid of January. RF injection in the RFQ should resume in the second half of January.

HEBT (High Energy Beam Transport) commissioning

This week was again very dense of remote sessions with great support from CIEMAT. Efforts were dedicated to commission the different Beam Instrumentation equipment installed in the HEBT line (SEM grid, Slits, Faraday Cup) and to solve setting issues with two power supplies of two quadrupoles magnets. Presently all Power Supplies (apart the Dipole Power supply for which urgent countermeasures are being taken) of HEBT magnets are working properly and correctly set-up.

Beam Dump

The installation of the planned upgrade in the deaeration loop (oxygen control loop) of the Beam Dump started this week and it is planned to last until 18 December.

Global Alignment survey

The planned global alignment survey of the LIPAc has been anticipated to start in December after the facility inspection. Preparation of instrumentation, training and inspection in the vault were carried out this week.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.

Weekly LIPAc highlights (30/November-4/December)

Injector conditioning

The Injector operation continued this week: the duty cycle (dc) was increased up to 50% with a very stable beam and 100mA of total extracted current from deuterium plasma. The target performance for the facility inspection (50%dc @100mA) has been reached well ahead of schedule. Next week (last week of operation before the facility inspection, scheduled for 16th December) the efforts will concentrate on decreasing the ramp-up time (it currently takes a few hours to ramp-up the injector to 50% of duty cycle).

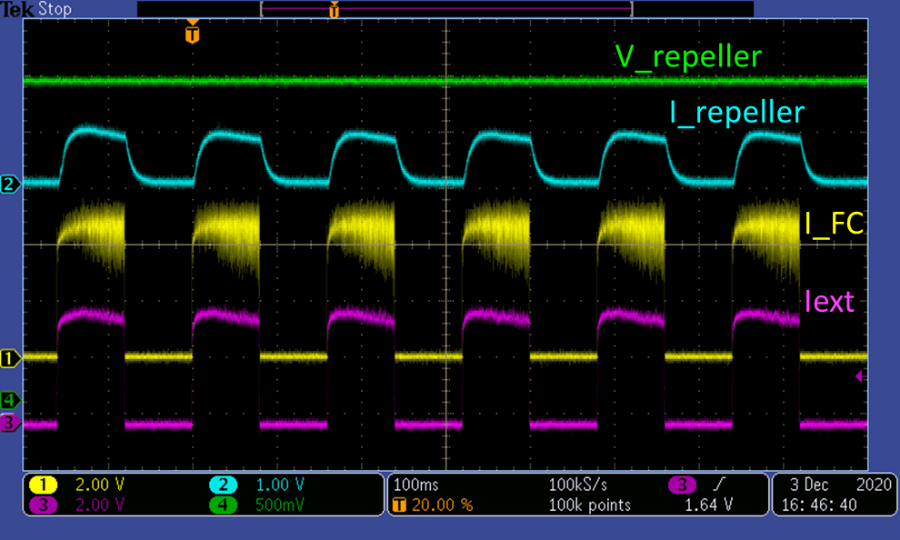

Screenshot of the injector oscilloscope on 03 December:

- Duty cycle: 50% (80ms/160ms)

- Total extracted current (red, Iext): ~100 mA

- Yellow: Faraday cup signal (I_FC)

- Blue: Current of repeller PS (I_repeller)

- Green: Voltage of repeller PS (V_repeller)

Radio Frequency (RF) System and RFQ cavities (Radio Frequency Quadrupoles)

This week the RFQ nominal vacuum conditions were resumed switching on all the cryo pumping groups.

The entire RF system has been progressively started to validate the upgrades implemented in a part of the RF chains and to train QST personnel on the entire start-up process (calibration of the RF chains, RF-RFQ interfaces checks). This afternoon we had successfully injected RF in the RFQ cavity!

Once completed the on-going tests and the upgrades validated, the modifications will be propagated in all the modules starting from next week, as soon as the RF system will be stopped. The target being to resume now the RF-RFQ conditioning in the second half of January.

HEBT (High Energy Beam Transport) commissioning

This week was very dense of remote sessions with great support from CIEMAT. The efforts focused on the commissioning and debugging of software for the different Beam Instrumentation equipment installed in the HEBT (SEM grid, Slits, Faraday Cup).

FMEA analyses

The Failure Mode and Effect Analysis (FMEA) of the LIPAc was initiated early this year with the objective to reduce hazards during its maintenance and operation phases. After 2 training sessions, the FMEA was discussed identifying hazards subsystem by subsystem during 26 working sessions. As a result, 59 actions and recommendations were proposed to improve the safety of the project and were included in the final report that was shared this week with the FMEA working group and group coordinators. The identified critical actions will be implemented as prerequisite before resuming the LIPAc beam operation. All the groups including the EU experts participated to this activity, so we can clearly call this achievement an all-hands work resulting from the collaboration of Japan and Europe within the Broader Approach.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.

Weekly LIPAc highlights (23-27/November)

Injector conditioning

The Injector operation continued this week: the duty cycle was increased up to 30% with a very stable beam and 100mA of total extracted current from deuterium plasma. The vault will now be predominantly closed to continue the conditioning of the Injector in preparation of the facility inspection. The target performances for the facility inspection (planned on December 16) is 50% duty cycle at 100 mA of total extracted current.

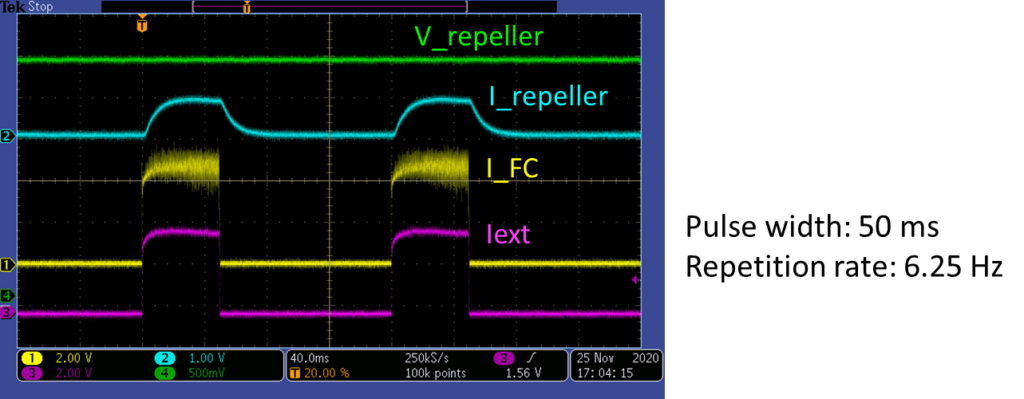

Screenshot of the injector oscilloscope on 25 November:

- Duty cycle: 31.2% (50ms/160ms)

- Red: Total extracted current (Iext)

- Yellow: Faraday cup signal (I_FC)

- Blue: Current of repeller PS (I_repeller)

- Green: Voltage of repeller PS (V_repeller, -4.5 kV)

RadioFrequency (RF) System

The RF team concluded several important activities this week:

- The issue on the High Voltage Power supply 3A (HVPS3A) was solved with continuous remote support from JEMA.

- The upgrade of the PSYS (Protection system) interlock was completed and installed on one RF module. The modification of the threshold levels of PSYS VSWR (Voltage Standing Wave Ratio) card were completed on the same module.

- The anode box upgrade to decrease the overheating at the circuit board was successfully implemented in one module.

The plan is to start next week the entire RF system to validate the upgrades implemented in a part of the RF chains and to train QST personnel on the entire start-up process. Once the upgrades validated, the RF system will be stopped and the upgrades extended to all the modules.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.

Weekly LIPAc highlights (16-20/November)

Injector conditioning

This week on LIPAc the Injector operations were resumed and beam extraction started!

The duty cycle was progressively increased and reached quickly 20% at the end of the week, with 100mA of total extracted current from deuterium plasma. No issues were observed in the high voltage stability. The vault will now be predominantly closed until mid of December to continue the conditioning of the Injector in preparation of the facility inspection.

HEBT (High Energy Beam Transport) commissioning

The HEBT vacuum system was successfully resumed and reached nominal level for beam operation. A long run test to monitor stability of the cryopumps is on-going.

The HEBT magnets commissioning is ongoing with continuous support from CIEMAT.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.

Weekly LIPAc highlights (9-13/November)

Start-up of Injector

The PPS test and the HV tests for the injector were successfully performed on Tuesday and Wednesday. The Deuterium gas injection was resumed on Wednesday afternoon but after few hours the pressure in the injector vacuum chamber started to rise. Even at low gas flow rate the stability of the vacuum was not satisfactory. Today the previous configuration using the oil vane rotary pump was reinstalled and vacuum resumed. Plasma production was immediately started to resume the conditioning of the ion source. The vault will now be predominantly closed until mid of December in preparation of the facility inspection.

HEBT (High Energy Beam Transport) commissioning

HEBT magnets – The HEBT quadrupole magnets functional tests were completed for 6 magnets with remote support from CIEMAT: individual automatic cycling tests, simultaneous cycling test and powering at maximum level were carried out this week.

HEBT vacuum – HEBT vacuum functional tests were started resuming the operation of the cryopumps and all went smooth. It is planned to run a long stability test.

The start-up behaviour of the 2 freshly regenerated ionic pumps was tested and demonstrated the effectiveness of the regeneration process. The remaining 2 ionic pumps will be regenerated after the facility inspection.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.

Remote data transfer success

A demonstration of data transfer from the Rokkasho BA site to F4E Garching was conducted on 23/10/2020 through a data diode. The newly connected Central Control Room was used, which is located in the Remote Experimentation Center. Data was transferred successfully, providing a read-only access to all LIPAc live data channels, as a demonstration of remote participation to be used in future LIPAc accelerator operation.

General LIPAc status of last week 45 (2-6/November)

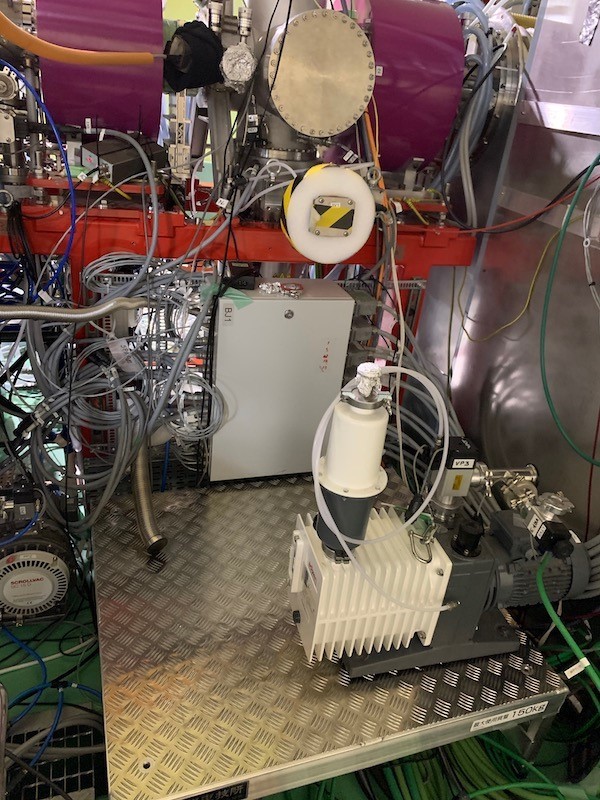

Maintenance of Injector vacuum

The replacement of the oil rotary vane primary pump with a dry multi root pump was successfully completed. Performance tests of the oil rotary vane pump and of the dry multi root pump were carried out to ensure adequate performance in pumping H species. The results are considered satisfactory to proceed with the conditioning of the ion source in preparation of the facility inspection. Longer tests will be performed after the facility inspection to further assess the dry pumping performance in pump H2 at high gas flow rates.

It is planned to resume the injector conditioning on 11th of November.

HEBT (High Energy Beam transport) commissioning

Checks and fine tuning of the HEBT magnets with CIEMAT remote support are on-going.

The regeneration of one of the four ion pumps of the HEBT was completed successfully. One more ion pump will be regenerated next week before the start of the Injector operation. Two remaining pumps are scheduled to be regenerated after the facility inspection (after mid-December).

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.

General current status and a nice technical achievement of last week 44 (26-30/October)

Maintenance of Injector vacuum

After the replacement of the turbomolecular pump last week, this week the replacement of the oil rotary vane primary pump with a dry multi root pump was performed. Operating the injector vacuum system with oil free pumps is considered a major improvement and will eliminate the risk to have oil contamination in the vacuum chamber. Along with the replacement of the pump, performances tests of the oil rotary vane pump and of the dry multi root pump are performed to ensure similar and adequate performances in pumping H species. Next week the tests will be completed and the injector vacuum chamber will be pumped down to nominal vacuum: it is planned to resume the injector conditioning on 9th of November.

HEBT (High Energy Beam transport) commissioning

Checks and fine tuning of the HEBT magnets were resumed with CIEMAT remote support. We are facing some issues with two power supplies of two quadrupoles magnets of the second triplet. Investigations are on-going to minimize the impact on the schedule.

The replacement of the cooling pipes network for the HEBT scrapers in the vault was completed and successfully tested.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.