The 9th LIPAc Technical Meeting (LTM09) was held at the IFERC Site in Rokkasho, Japan, from 19th to 22nd April 2016. More than 40 experts from different involved institutes, including CEA (Saclay, France), INFN (Legnaro, Italy), QST (Rokkasho, Japan), CIEMAT (Madrid, Spain), F4E (Garching, Germany) and the IFMIF/EVEDA Project Team; attended the meeting. In addition, Japanese experts from KEK and J-PARC attended on behalf of QST.

Many satellite meetings were held, with devoted discussions on most of the accelerator systems, including the MEBT (Medium Energy Beam Transport), HEBT (High Energy Beam Transport) and the Beam Dump; the control systems, including vacuum system integration and its overall process management, the control room configuration; the different phases of LIPAc commissioning, including integrated operation scenarios and beam dynamics issues; and the cryomodule assembly.

During the LTM, much detailed technical information was presented, highlighting the significant progress that has been made for the manufacture and installation of various components since the previous LTM08 held in Garching (Germany) on 24-26 November 2015.

The main outcomes presented during the meeting are listed below:

• Injector

Over the last 6 months injector operations have been very intense: 3 measurements campaigns were carried out as well as curative and major preventive maintenance. The deuteron beam commissioning performed in December 2015 gave promising results, the emittance met specifications at 20 % and 50 % duty cycle for currents of 110 mA at the level of the beam stop. In March 2016, the measurement campaign with a proton beam, which is a scaled version by a factor of 0.5 in intensity and energy, but with the same perveance as a deuteron beam, enabled to find a good working point at 10 % duty cycle. The last measurement campaign was very effective thanks to the careful maintenance performed and to Tracewin simulations which made it possible to determine the most interesting sets of machine parameters giving the best beam characteristic

- RF power systems

Remarkable progress was made for the RF system, with the delivery and installation inside RF power supply area of the Accelerator Building of all of the HVPSs and the first three RF Modules for the RFQ. The main cable trays, panel boards and grounding systems have also been installed, and the transformers and the HV breakers on the electrical platform are complete.

The four RF modules for the SRF LINAc have been manufactured, and the first unit has been partially tested and will soon be ready for shipment. It will be shipped to CEA Saclay for integration on the Sathori Test Stand.

- RFQ

The RFQ super module installation was successfully completed according to the schedule presented at LTM08 (Garching, Germany). The bead pull measurements will commence on 25/04/16 and will be completed by the end of July after 3 campaigns of measurement. The RFQ will then be relocated to its final position immediately afterwards.

The RFQ cooling skid and accessories are at Rokkasho and the water cooling skid requires some adjustment before its final installation/site commissioning.

- MEBT

The MEBT arrived in Rokkasho in March 2016, and was temporarily positioned inside the Accelerator Vault by the end of March. The electrical cubicles and other electrical equipment are expected to arrive in the middle of July, while the cooling skid, piping and associated accessories are currently being manufactured

- D-Plate

The D-plate was installed inside the Accelerator Vault in a temporary position, in April 2016.

- SRF Linac

While licensing activities for the complete cryomodule continue, the formal approval of the cavity design by KHK was obtained representing a great success for those involved.

Manufacturing contracts for all critical components have now been placed, and the tender process for a number of non-critical-path items has also been launched. Agreement has nearly been reached on the definition of the requirements for the clean room to be constructed at Rokkasho, and the tendering process for the clean room’s construction is expected to start by June.

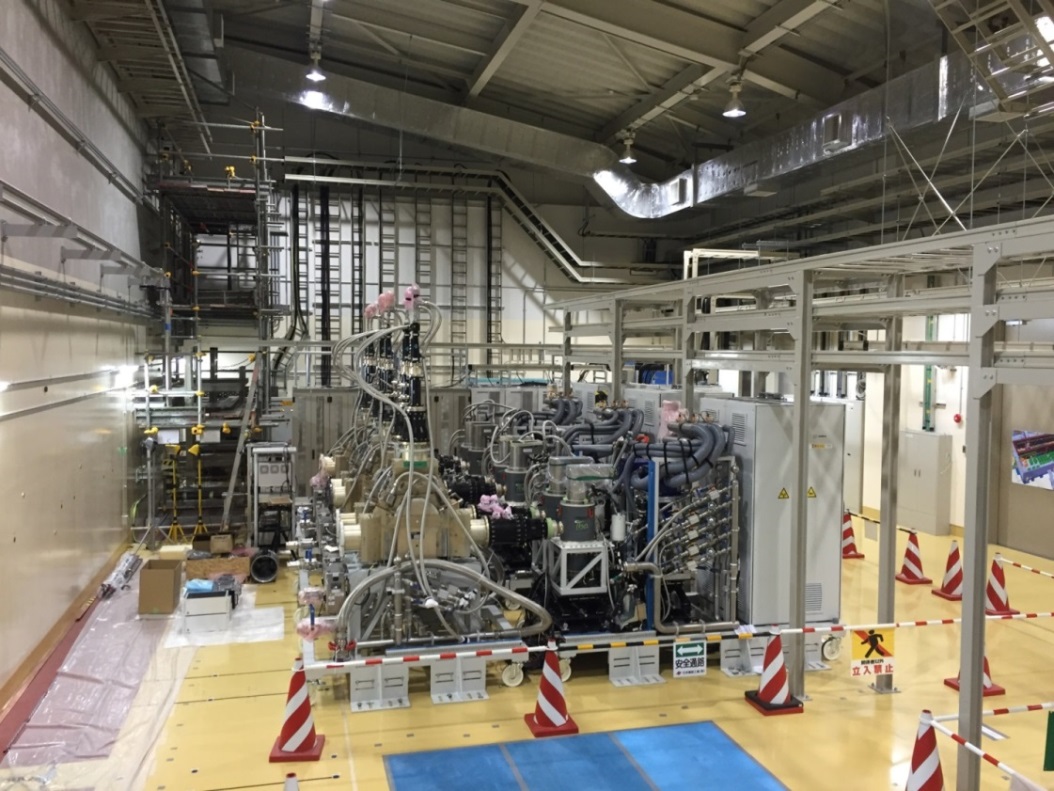

- Cryoplant

The main cryogenic system components, including He compressors, oil removal system and cold box, have been manufactured and delivered to Rokkasho.

The requirements for the licensing of the cryoplant have been clarified. The cryoplant distribution piping and equipment are currently being designed.

- HEBT/Beam Dump

The HEBT water cooling skid, which will cool the magnet of the MEBT and HEBT, arrived in Rokkasho in January 2016. It was positioned inside the Accelerator HEX room and the piping is expected to start after the final positioning of the MEBT, which will intervene after the final positioning and back out of the RFQ.

A number of manufacturing contracts for the HEBT are ongoing, including the construction of the quadrupole and dipole. The design of the beam chambers is complete and the technical specifications have been prepared. The remaining components, i.e., power supply, supports, magnets coil system, vacuum pumps and associated equipment; have also been designed and are being procured.

Design for manufacture continues for both the Beam Dump low alloy steel shielding and mobile shielding, with manufacturing expected to start for both at the end of May 2016. Final assembly and acceptance tests are expected to commence in September. Manufacturing is progressing well for the Beam Dump cartridge.

- Control system

The dedicated Control Systems and LIPAc Operation satellite meeting was fruitful. It was identified that the integration of the different LCS into the CCS is on the critical path and mitigation actions should be considered. It was agreed also the need to tackle the various operational issues e.g. setup of the vacuum systems, identifying the thresholds for the MPS and setup of common operating procedures. An operating procedure for phase B, including a start-up procedure needs to be prepared urgently and missing operations with possible proposed configurations must be identified.

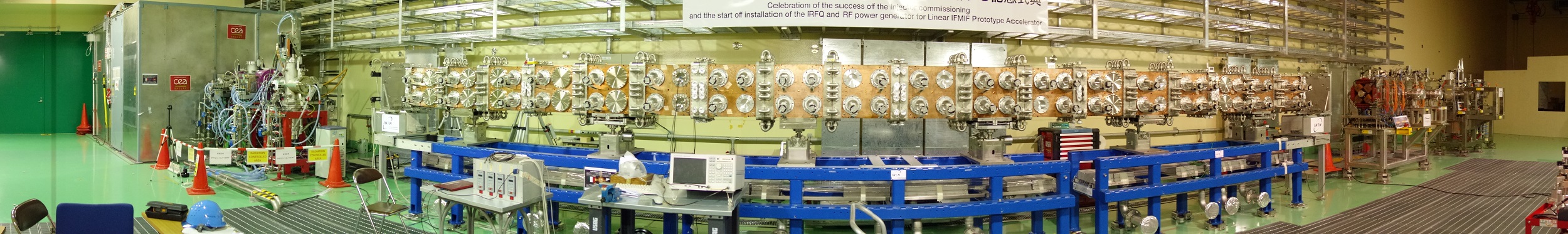

The meeting was successful in spite the overlapping of Broader Approach Steering Committee half-yearly meeting (BASC) and LIPAc ceremony. The main actors who have done all the technical work could also attend LIPAc ceremony and finally to the pleasant banquet that took place in the Kizan restaurant in Misawa, together with all ceremony participants for the celebration of success of the Injector commissioning and the start of installation of the RFQ and RF power generation for the LIPAc.

See you at the next LTM10 at the end of November 2016, again in Rokkasho (Japan)