25 September 2019

After the completion of operation corresponding to the phase B, the maintenance activities have started mid of August as planned alongside the preparation of the next phase: phase B+. In this long maintenance period, it is important to carry-out both the curative maintenance of components that were malfunctioning and the preventive maintenance to ensure a better reliability and availability of the systems for the next operation campaigns. The maintenance activities are planned targeting to resume Injector continuous wave operation and Radio-Frequency Quadrupole (RFQ) conditioning before end of 2019, so that LIPAc operation can restart in the second quarter of 2020. In this first period higher priority has therefore been assigned to the Injector and RF/RFQ systems maintenance.

Maintenance activities of the Diagnostics-Plate and of the vacuum systems have also started; maintenance of the Medium-Energy Beam Transport line (MEBT) are planned in December. Specific activities on the beam instrumentation will be carried out in November with EU experts from CEA and INFN on-site. The final beam instrumentation checkout will take place after the installation of the MEBT extension line.

The maintenance of the ancillaries is on-going and many activities have already been completed, such as electrical network distribution, secondary cooling system, Personnel Protection System, Accelerator vault crane. The cryoplant maintenance activities will be carried out in the first quarter of 2020.

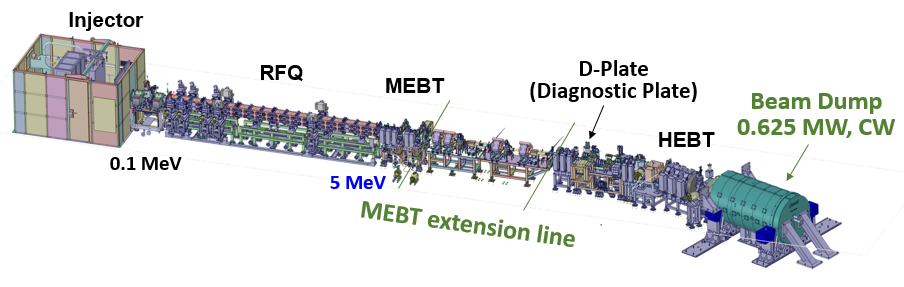

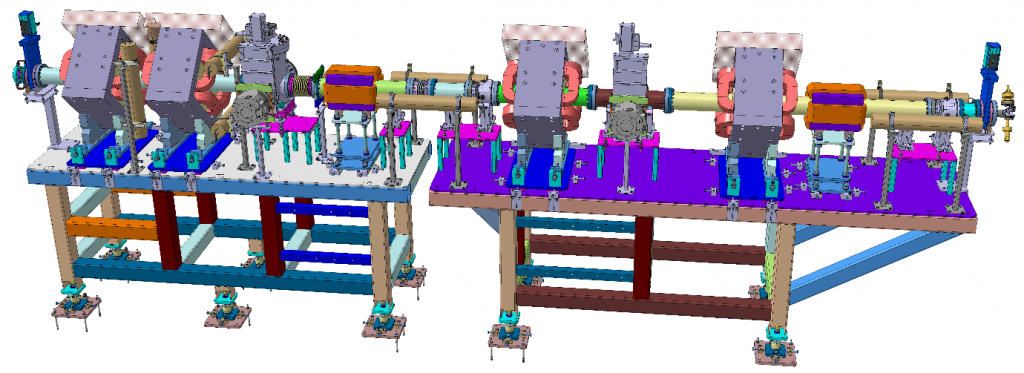

The upgrade of LIPAc into its future phase B+ configuration, with its High Energy Beam Transport line (HEBT), is also the goal of this maintenance period. The MEBT extension line has been designed to transport the beam at 5 MeV instead of the cryomodule. It is composed of quadrupoles to focus the beam, steerers to correct its trajectory, Beam Position Monitors to monitor the beam orbit, a vacuum chamber to host a Residual Gas Bunch Length Monitor, Beam Loss Monitors and turbo-pumps for vacuum pumping. The components of the MEBT extension line are currently being procured or manufactured.

The Low Power Beam Dump which was used during phases A and B will be removed. The HEBT is positioned in its final position together with the Diagnostics Plate, and the LIPAc Beam Dump for full beam energy will be connected to the beam line.