Injector

The injector conditioning using 6mm Plasma Electrode is currently on-hold waiting for the procurement of the cooling plates of the Power Supplies of the two Solenoid magnets. The plasma conditioning is on-going during the day when the vault is closed, and every night and weekend.

Radio Frequency (RF) System and RFQ cavity

RF injection in the RFQ cavity up to 5% Duty Cycle (DC) was completed and conditioning up to 10%DC has now started with remote assistance by INFN. The RF system is stable and no major event are observed. In the evening the system is let for night conditioning to NAT operators, while during the day time the on-site experts move to higher DC following the procedure defined with INFN requiring always tuning/adjustment of the system: for example the fine tuning of the mass flow rate balance among HVPS (High Voltage Power Supplies) and RF modules was necessary one day this week.

Medium Energy Beam Transport (MEBT)

The Personal Protection System (PPS) interface tests with the bunchers SSPA (Solid State Power Amplifiers) were successfully completed and the RF condition of the buncher cavities was started this week and is currently on-going.

Beam Dump

After the completion of the connection of the cooling loop to BD cartridge in the vault, the cartridge was successfully filled with water and the BD skid was successfully run in the two operational modes to be used for beam operation. Achieving the water circulation in the BD cartridge is a major achievement for the project and for the accelerator community worldwide!

This could be achieved only thanks to the strenuous support of CIEMAT experts connected remote daily with Rokkasho starting from 7 am CEST and the on-site team providing an extensive support to CIEMAT experts allowing a wide amplitude of work although the time zone difference between Europe and Japan!

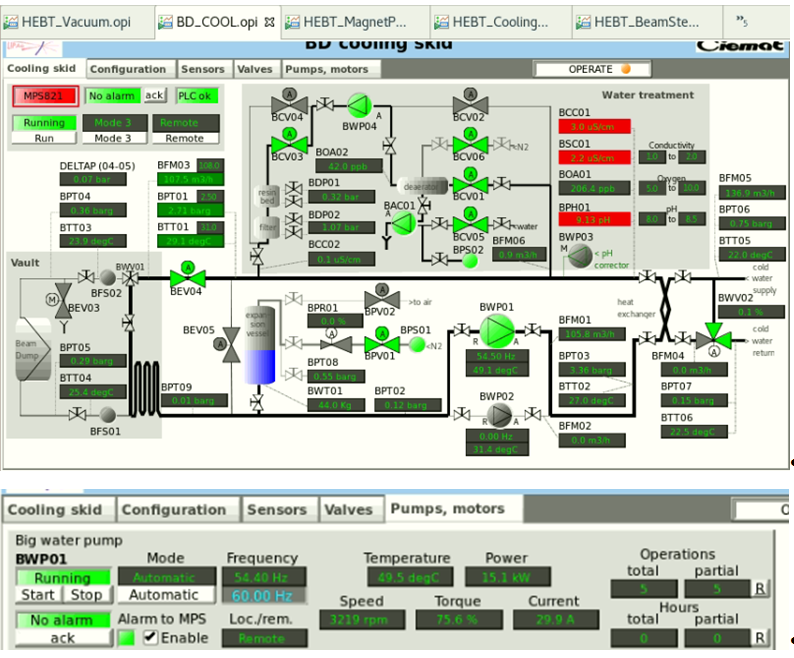

OPI of the BD cooling skid. It can be noticed that:

- The main pump of the cooling skid BWP01 is running at nominal speed (60Hz achieving 108m3/h

- The pump of the water treatement line (ph corection) BWP04 is operational, as well as the deareation loop (BAC01 vacuum pump).

Control System

The integration in EPICS of the MPS (Machine Protection System) signal from the Common Chiller is on-going. The enhancement of the OPI from the new CCR (Central Control Room) is showing good progresses.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.