Injector

After the completion of the PPS test (for the authorization to proceed with the beam extraction), the proton beam extraction has started with the Plasma Electrode having a 6 mm hole. The ramp-up was rather quick: 10-40 mA of proton beam at 5-10% duty cycle were achieved, with good stability and good beam emittance. The Injector is operative from the Central Control room.

Radio Frequency (RF) System and RFQ cavity

The start-up of the RF system with the calibration of the LLRF (Low Level RF) and the RF chains continued. The check of RF noise issue on the RF system components was systematically investigated; the situation is now improved thanks to remedial actions quickly implemented: grounding meshing is being improved and the newly installed PSYS-LLRF interlock circuit has been modified to inhibit the EMC perturbation. A MicroBox PC used in RF Water Cooling System (WCS) was damaged and it is being replaced: monitoring of the WCS status is essential to hand over at low DC to NAT operator the conditioning during the night. The planned activities to integrate the new RF coupler temperature monitor into the LCS started (remote sessions with INFN took place and are planned).

RF injection trials in the RFQ cavity were successfully carried out for the first time from the Central Control Room (CCR)! During RF injection the RFQ vacuum was stable and the temperature rise at the RFQ couplers was <1°C.

Beam Dump

As part of the BD skid commissioning, the functionality of the recently modified deaeration loop has been confirmed for the first time: under active water circulation in the BD skid the water conductivity was lower than 1uS/cm; operating the vacuum pump of the deaeration loop the dissolved oxygen was decreased from ~2000ppb to ~1600ppb in 20 min.

Currently CIEMAT support is focused on solving PLC issues to adjust sensors and flowmeters calibration and allow the pumps to work in automatic mode.

Beam Instrumentation

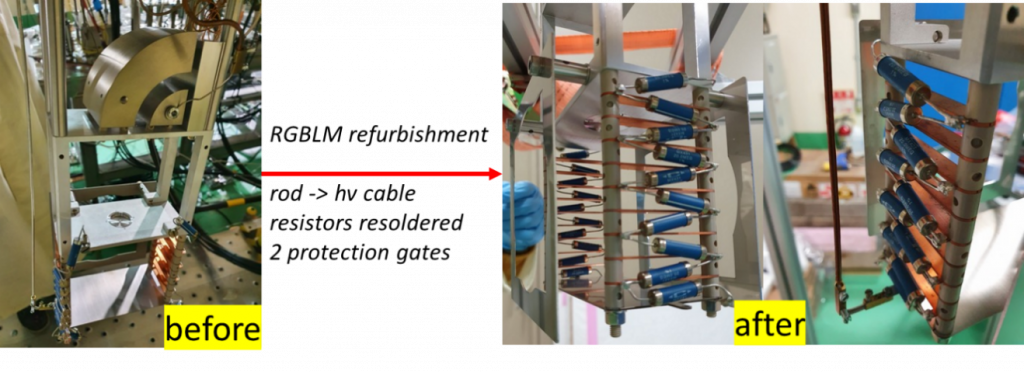

After delivery onsite of all the components, the final modification of the RGBLM (Residual Gas Bunch Length Monitor) was completed and the refurbished sensors is now ready to be installed in the vault. The intervention is planned in the week from 29th of March to 2nd of April.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.