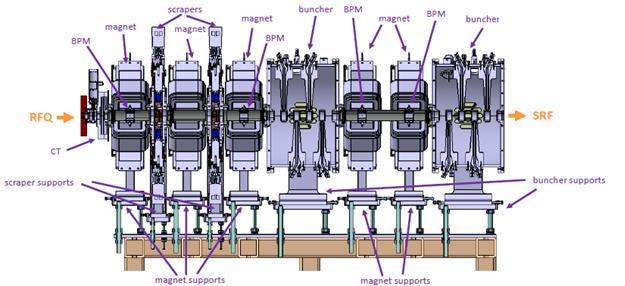

The Medium Energy Beam Transport (MEBT)

The main function of the MEBT is to match efficiently the RFQ output beam profile to the SRF input, transversally and longitudinally. The longitudinal forces are applied to the beam by means of two RF resonant cavities. A 5-gap interdigital H-mode configuration has been selected as a buncher cavity as the best compromise in terms of total power dissipation, power density, and space occupied. The radial dimensions of the beam are controlled for injection into the SRF Linac by one quadrupole triplet and one quadrupole doublet. The transverse position of the beam is corrected by the magnetic steerers integrated into the quadrupoles. In order to cut the beam edges and to determine beam losses, the unmatched particles coming from the RFQ are collected by two 4-axis movable metallic plates, called scrapers, inserted between the magnets of the triplet. To achieve the vacuum conditions required by the proximity of the RFQ and Superconducting Radiofrequency Linac, a pumping system in the range of 103 l/s for H2 will be installed at the vacuum ports of the bunchers.

The detailed design activities of the main components have been accomplished:

– the magnets have been designed and the first unit was validated on a magnetic test bench in July 2012 ,

– the beam halo and out-of-energy particles coming from the RFQ are stopped in two movable scrapers, designed for a maximum 500 W beam power deposition. It has been designed for easier maintenance,

– the bunchers, currently in the detailed design phase, are under study with particular attention to the cooling system, the objective being to comply with the main requirements with an accelerating voltage of 350 kV and a total power of 6.6 kW to be dissipated. A first prototype with aluminum stems for low-power tests was produced end of 2012 and the first complete buncher for high-power delivered by the beginning of 2013.

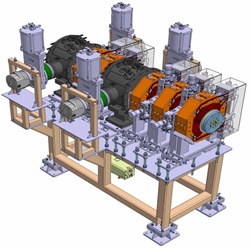

Early 2015 the integration of all the components in the MEBT will be completed. The delivery to Rokkasho is planned April 2015.