Beam instrumentation consists of diagnostics aiming at monitoring and controlling all the necessary beam characteristics along the accelerator, and thus are the basis for its successful operation, right from the early beam commissioning phases up to routine operation. Except for some specific devices, most of the beam diagnostics must therefore be able to provide information for pulsed and continuous beams equally, withstanding minimum to maximum beam current (power).

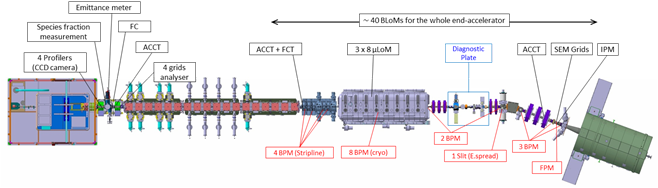

A full set of non-intrusive diagnostics to monitor and to characterize the beam all along the accelerator has been developed: current monitors of various types (AC and DC current transformers, fast current transformer), 20 beam position monitors (8 of them at cryogenic temperature), beam profile monitors (based on ionization and fluorescence of the residual gas), around 40 beam loss monitors (ion chamber Large Hadron Collider type), micro-loss monitors (based on chemical vapour deposition) diamond operating at cryogenic temperature), bunch length monitor (residual gas). For short chopped beams, interceptive devices as secondary emission monitor grids and slits will be used for emittance and energy spread measurement.

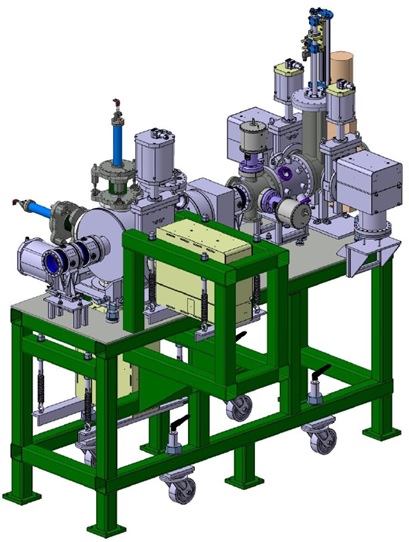

In addition, a Diagnostic plate (D-Plate) combines specific diagnostics to characterize the beam during commissioning with beam, and will be located first at the exit of the RFQ and MEBT during RFQ commissioning, and second at the exit of the SRF Linac during LIPAc normal operation.