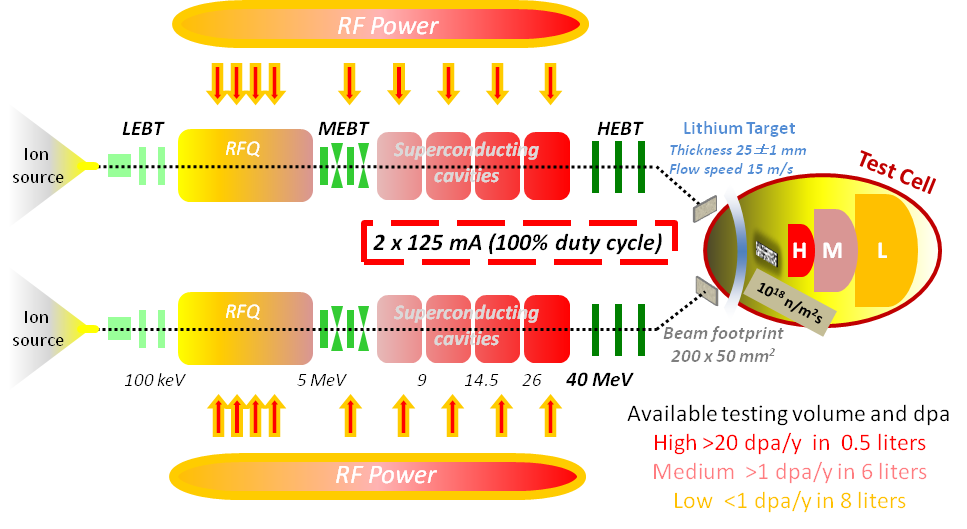

IFMIF, the International Fusion Materials Irradiation Facility, will generate neutrons with an energy spectrum similar to those occurring in a DT (deuterium-tritium) fuelled nuclear fusion reactor. A commercial fusion reactor will require materials capable of withstanding 150 dpa (dpa is the typical unit used to describe neutron-induced materials degradation, indicating average displacements per atom in the bombarded material), which nowadays is an unexplored region. The design of a reactor demands an understanding of which materials can be used and what mechanical properties they will retain after years of operation. IFMIF is a unique tool to learn this. In IFMIF neutrons will be generated by bombarding liquid lithium with accelerated deuterium ions (deuterons). There will be suficient to cause damage equivalent to that in the first wall of a fusion power plant.

Three main facilities will form IFMIF: two accelerators, a target, and a test cell. All three are under validation and design refinement in the current Engineering Validation and Engineering Design Activities (EVEDA) phase, which is due to be completed in 2017.

The IFMIF/EVEDA phase

The IFMIF Engineering Validation and Engineering Design Activities (EVEDA) aim at producing a detailed, complete and fully integrated engineering design of IFMIF and at validating continuous and stable operation of prototypes of each IFMIF subsystem:

The validation activities have been the subject of a successful Japan-Europe scientific collaboration. In order to produce the experimental backing of the IFMIF Design during the EVEDA phase, 3 major prototypes have been designed and manufactured:

- an Accelerator Prototype (LIPAc) at Rokkasho, fully representative of the IFMIF low energy (9 MeV) accelerator (125 mA of D+beam in continuous wave) to be completed in June 2017;

- a Lithium Test Loop (ELTL) at Oarai, integrating all elements of the IFMIF lithium target facility, already commissioned in February 2011, complemented by corrosion experiments performed at the LIFUS6 lithium loop at Brasimone; with the development of needed diagnostics and purification systems, will demonstrate that IFMIF’s liquid lithium loop is achievable.

- the High Flux Test Module (different designs) and its internals to be irradiated in a fission reactor and tested in the helium loop HELOKA, complemented the Creep Fatigue Test Module manufactured and tested in full scale at Villigen.