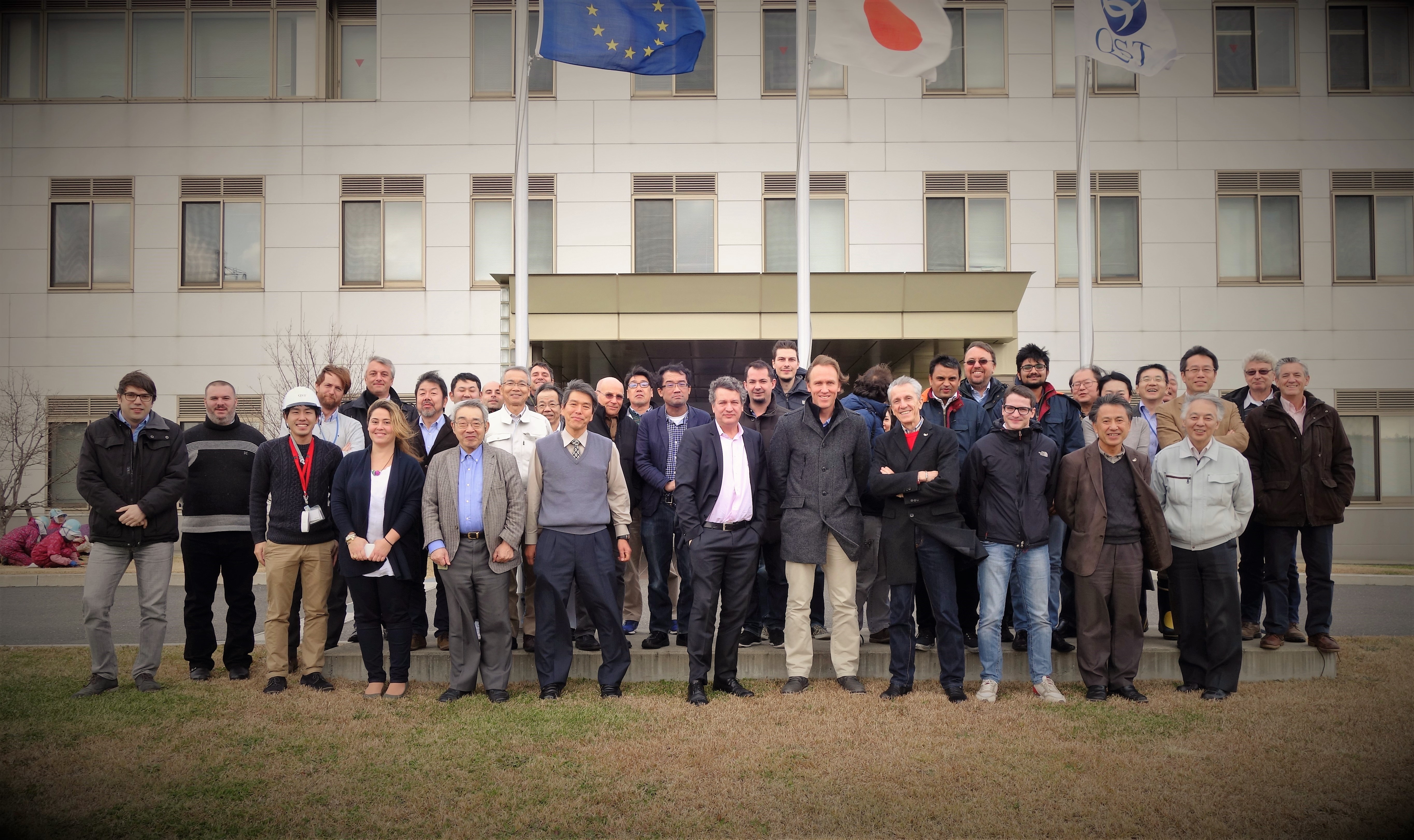

The tenth LIPAc Technical Meeting 10 (LTM10) was held in Rokkasho (Japan) from November 14th until 17th, where the current status of the design, manufacturing, installation and commissioning of the LIPAc accelerator’s components were discussed. More than 30 experts from laboratories in Europe, including CIEMAT (Madrid, Spain), CEA (Saclay, France) INFN (Legnaro, Italy); and Japan, including QST (Rokkasho, Japan) and KEK (on behalf of QST) attended the meeting, which was coordinated by the LIPAc Project Team and QST. In addition, videoconferencing was available to allow remote participation of EU colleagues who could not attend in person.

Detailed discussions were held to reach common agreement on the key technical issues that have arisen, and progress was reported on many aspects of the project. The following gives an overview of the progress made in key areas:

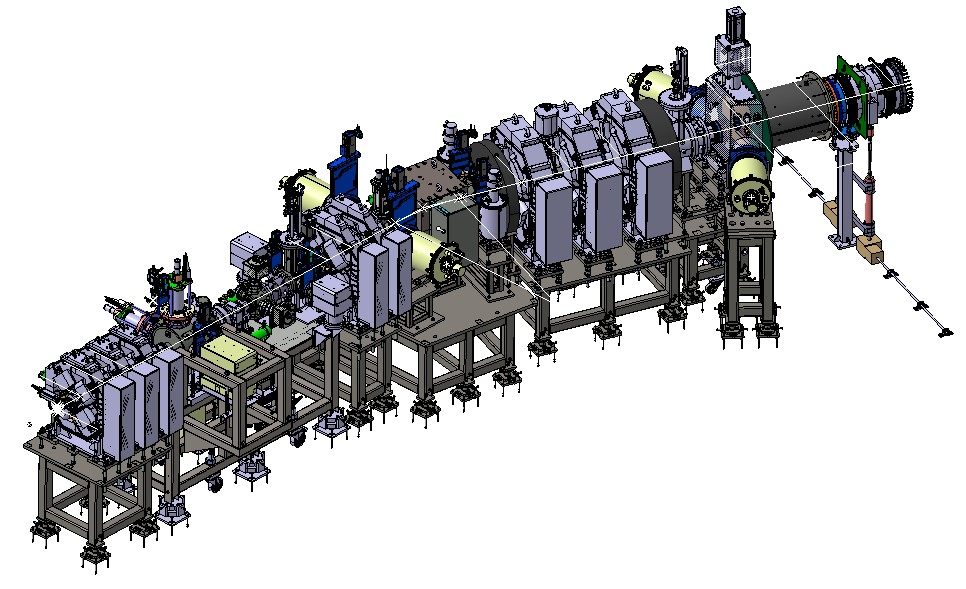

Injector:

Full commencement of phase “B” commissioning was announced, and the LEBT (Low Energy Beam Transport) was removed to allow final positioning of the RFQ. During the last campaign of Injector commissioning, a current of 112 mA with acceptable emittance in CW operation was achieved. While this falls short of the goal, this represents an excellent improvement. Further adjustments must be made to the accelerator column, followed by 24/7 beam extraction, to achieve the target parameters.

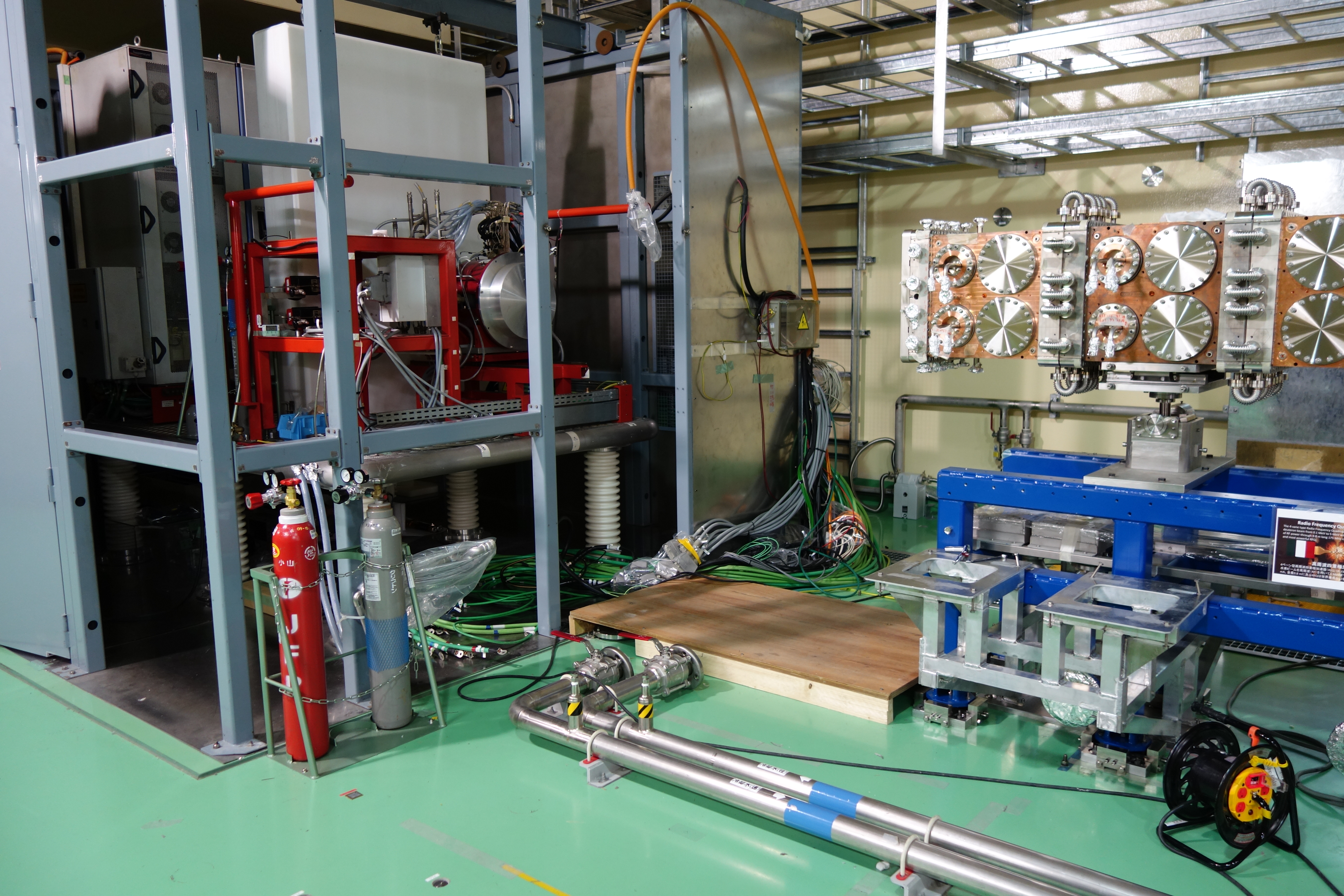

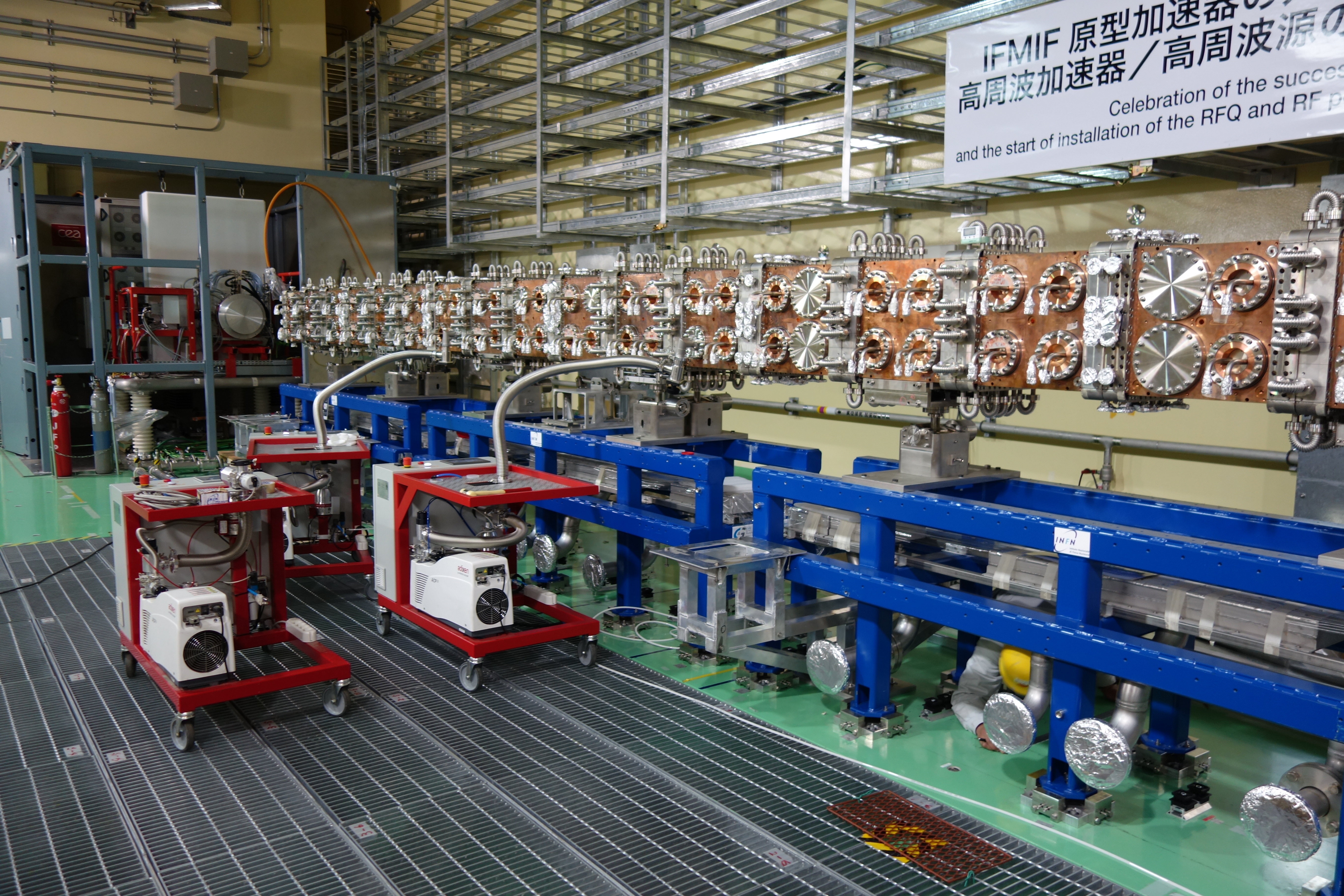

RFQ:

The bead pull measurements were successfully completed, and the final measured frequency was equal to 174.089 MHz. When scaled to the normal operating temperature of 20 °C and considering the effects of vacuum and beam loading, this is equivalent to 175.014 MHz. Following LEBT removal, the RFQ super modules were placed in their final position, and aligned within a tolerance of 50 µm. The RFQ was pumped down and the correct vacuum conditions for the three super-modules were achieved. The RFQ can now be baked-out before final assembly can proceed. Control cubicles and junction boxes were installed and are now being configured.

RF System and Coaxial lines:

Tangible progress was made since LTM09, which was held in April 2016. RF module 02 for the SRF LINAc was tested and sent to Saclay for Sathori test stand. After use in Saclay, it will be sent to Rokkasho for installation in Rokkasho. RF module 03 will be sent to Rokkasho on 30th of November 2016, together with the SRF LINAc coaxial lines, while RF module 04 is now in the final stages of preparation at Indra’s facilities, and is expected to be ready for shipment to Rokkasho in January 2017. The installation of the RF cooling system onsite is almost complete. The RFQ coaxial lines have been installed in preliminary position. Final positioning will be made after the connection is made to the RFQ.

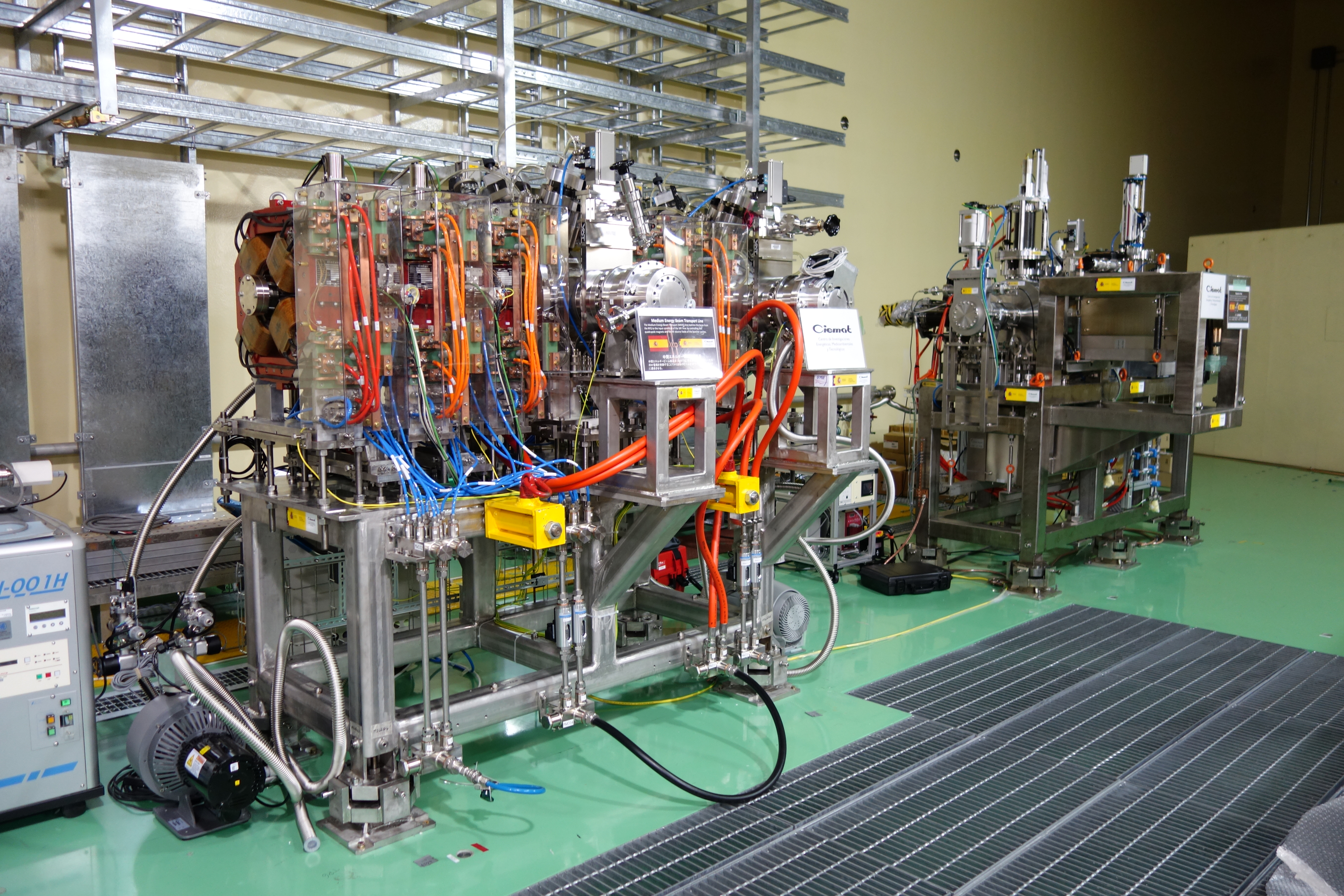

MEBT and D-Plate:

Most of the installation and commissioning activities of the MEBT and D-plate were performed in parallel during pre-commissioning last summer 2016. Preparation for the next installation campaign already started with the objective to reach the LIPAc phase B configuration (Injector-RFQ-MEBT-Dplate and LPBD) next year. The displacement of the MEBT to its final position is planned beginning of 2017. Once it is validated by an alignment survey, it will be followed by displacement and alignment of the Dplate. Then the ancillaries (cabling, piping, compressed air and vacuum) will be installed on both equipment and tested. The integration of LCD into CCS will conclude this campaign; at least for these two accelerator components, driving to their check out and commissioning.

SRF Linac and Cleanroom:

All the main components of the cryomodule are expected at CEA (Saclay, France) by the end of March 2017 and ready for shipment to Rokkasho by the end of April 2016. It was agreed that the assembly of the cryomodule will be performed at Rokkasho in dedicated clean room which will be available in Rokkasho by the end October 2017.

The Sathori test stand is prepared and awaiting commissioning of the power supplies and RF modules. CEA expect to start testing the cavities at the beginning of 2017

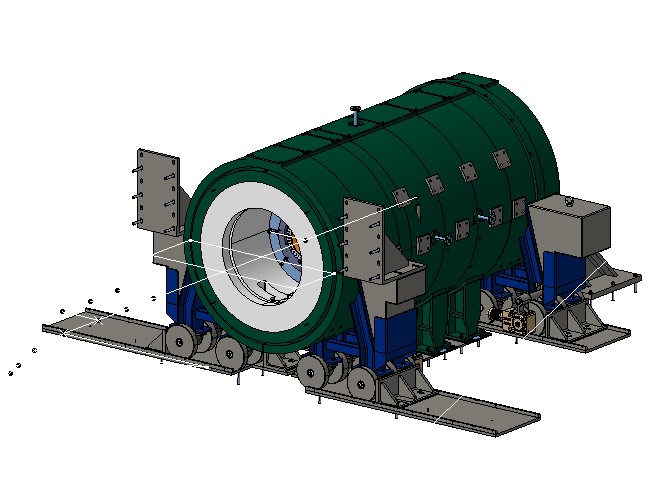

Cryoplant:

Most of the components for the cryoplant have been delivered to Rokkasho. The final components, including the helium buffer tank and the control cubicles, will be delivered during December 2016. The installation activities started during November, with the first major components being installed in their final locations and the commencement of piping works. Civil work associated with the cryoplant is also progressing with the construction of the foundations for the Nitrogen and Helium storage tanks.

HEBT/BD:

The HEBT manufacturing drawings have been completed and many components, such as the water cooling system, and associated pipe, fittings and valves; have been manufactured or procured and delivered to Rokkasho. 4 out of 5 HEBT support frames have been manufactured at CIEMAT, and manufacturing of the first quadrupole is complete. For the beam dump, the inner cone of the first prototype has been manufactured, and a second prototype is being manufactured. The acceptance tests for the beam dump shield are expected to proceed at CIEMAT in December 2016. The main steel shielding and mobile shielding manufacture is now in an advanced state, and final acceptance tests are expected in February 2017. The cooling system design continues, but manufacture will need to be accelerated to match with the current schedule.

Control system:

Phase B commissioning is approaching, and as such, the dedicated control configuration is required for the control system. An additional 42 signals are required, a test bench for the timing system has been prepared, and the program for data creation is being prepared. Local control system integration for phase B will include the RFQ, RF/LLRF, MEBT and D-plate. The Central Control System upgrade contract is expected to start in January 2017. Moreover the need for a beam simulation study to optimize the configuration of beam was recognized as being urgent. Data event recording tool must be implemented, and the operational screens in the control room are being prepared according to the needs of the different subsystems.

The next meeting LTM11 will be held between April and May 2017, with the location yet to be decided.